- #What file type is supported.by mach3 cnc software how to#

- #What file type is supported.by mach3 cnc software manual#

- #What file type is supported.by mach3 cnc software software#

- #What file type is supported.by mach3 cnc software Pc#

- #What file type is supported.by mach3 cnc software series#

It may be the case that that the configuration information is already saved as a file on the PC, but I simply don`t know what I looking for which makes it somewhat difficult.

#What file type is supported.by mach3 cnc software Pc#

When the old PC went bang I took it to a local PC repair shop and they recovered everything and reinstalled it onto the new PC, it all loaded OK but would run. Please find below two images as requested, is there supposed to be any illuminated lights of the HG08 board? I hope that makes sense and hope that someone can assist. The problem that we have is that the head/gantry will not move on a cursor command even though the numerical values change and we are able to load a file onto the Mach3 program. I am trying to find a Mach3 field technician that would attend our premises TW4 7EA (Heathrow, London) on a fee basisi to re-configure the system/Mach3 due to a computer malfunction. MeshCAM comes with a variety of configurations built-in and we will provide a custom configuration at no cost if you need changes made.We have a CNC plasma table we bought from a company call Plasma Frame Limited (no longer trading). A good CAM program will be configurable to work with any "normal" machine controller if it uses gcode.

#What file type is supported.by mach3 cnc software manual#

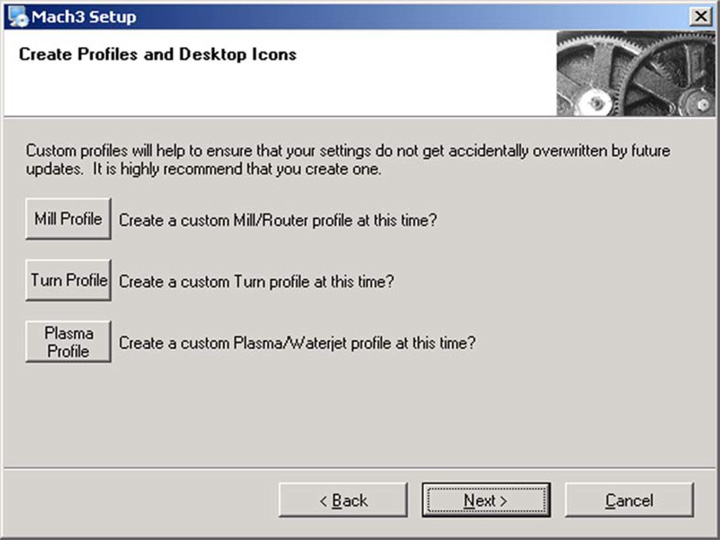

You would only need to buy Mach3 with MeshCAM if you are building your own mill or doing your own CNC conversion on a manual mill and do not yet have a CNC controller.Įvery CNC controller uses a slightly different dialect of gcode. Both work well with MeshCAM.Ī frequent question prior to purchase is, "Do I need to get Mach3 with MeshCAM?" If you have a working CNC mill then the answer is "No". Most people will find Mach3 easier to get up and running and it is the preferred program of GRZ Software. DOS CNC controllers are not recommended for complex gcode paths.ĮMC and Mach3 and both great programs and together represent the majority of the small-to-mid CNC mill market. There are several other programs that run under DOS but these are older and have not been updated to take advantage of the latest PC advances. EMC is free and runs on Linux while Mach3 is a commercial program that runs under Windows. Two examples of these programs are EMC, the Enhanced Machine Controller and Mach3. For most small-to-mid machines, a PC is used with a special program acting as a CNC controller.

#What file type is supported.by mach3 cnc software software#

Some larger mills have integrated computers or controllers that have this software built in. CNC ControllerĪ CNC controller is a program that takes the gcode file from your CAM program and tells the motors on the mill exactly how they should move in order to cut your part. Like a 3D CAD program, a 3D CAM program can also work on flat objects as long as they are contained in a 3D file. MeshCAM is a 3D CAM program that is able to take a 3D file and calculate a toolpath to send to your machine. Gcode is a standard file format to represent a toolpath and is supported by almost every mill.

#What file type is supported.by mach3 cnc software series#

A toolpath is the series of moves the mill must make to cut the object from the stock without overcutting or gouging the part. The output from a CAM program is a toolpath contained in a gcode file. Like CAD programs, CAM is available in 2D or 3D versions based on the type of input file they take.

#What file type is supported.by mach3 cnc software how to#

CAM programs are responsible for taking the output from a CAD program and doing the required calculations to tell a milling machine how to cut an object from the stock material. CAMĬAM stands for Computer-Aided-Manufacturing. It is important to note that a 3D CAD program is still able to represent flat objects- it will just take the extra step of also representing the depth of the part in addition to the profile. A short list of some 3D CAD programs can be found HERE.

The STL format is widely supported and is a very reliable way to move a file between programs without compatibility problems. There are several common file formats used in 3D CAD but MeshCAM operates on STL files. These CAD programs tend to be a little more complicated but they can represent very complex models in a way that is immediately useful for CNC manufacturing. The output from a 3D CAD program is a file with a complete 3D object that is ready for manufacturing. While the drawing itself may include dimensions and views that represent what a real part will look like, the result is still a flat drawing. 2D CAD programs produce only flat drawings.

In general, they can be divided into 2D and 3D CAD. There are thousands of CAD programs available and many are very good. As the name implies, this is the program you will use to design the parts that you plan on machining.

0 kommentar(er)

0 kommentar(er)